EASY INSTALLATION

Time-saving clip installation system that reduces construction time and minimizes mistakes.

Quick Installation Guide

Impact Resistant

Fire Safety

Featured Products

|

Nichiha EX Series panels are cement bonded fibrous wood particle products that are pressed with a surface texture. They are cut to a standard length of 3030mm or 1820mm with an effective cover width of 455mm and 16/18/21mm nominal thickness. The horizontal edges of the panel are machined with a complementary tongue and groove profile. For the 1820mm panels, the vertical edges have a tongue and groove profile as well. A compressible sealing strip is bonded onto the tongue which enables the panels to fit neatly together to form a weather resistant joint. The panels have been pre-finished using a durable multi-layered paint process to simulate a range of textured finishes. There is a range of color matched accessories including pre-formed external corners, joint sealants, various metal accessories such as trims and touch-up paint kits to speed installation and enhance the project finish and appearance. EX Series 3030 / V SeriesDimensions:455mm[W] × 3030mm[L]

EX Series 1820Dimensions:455mm[W] × 1820mm[L]

|

|

|

Nichiha EX Series panels are cement bonded fibrous wood particle products that are pressed with a surface texture. They are cut to a standard length of 3030mm or 1820mm with an effective cover width of 455mm and 16/18/21mm nominal thickness. The horizontal edges of the panel are machined with a complementary tongue and groove profile. For the 1820mm panels, the vertical edges have a tongue and groove profile as well. A compressible sealing strip is bonded onto the tongue which enables the panels to fit neatly together to form a weather resistant joint. The panels have been pre-finished using a durable multi-layered paint process to simulate a range of textured finishes. There is a range of color matched accessories including pre-formed external corners, joint sealants, various metal accessories such as trims and touch-up paint kits to speed installation and enhance the project finish and appearance. EX Series 3030 / V SeriesDimensions:455mm[W] × 3030mm[L]

EX Series 1820Dimensions:455mm[W] × 1820mm[L]

|

Time-saving clip installation system that reduces construction time and minimizes mistakes.

Prefinished panels eliminate the need for messy mortar or costly masonry-skilled labor.

No-fuss products. Little ongoing cleaning or regular maintenance needed. Bring your vision to life and ensure it looks great for years to come.

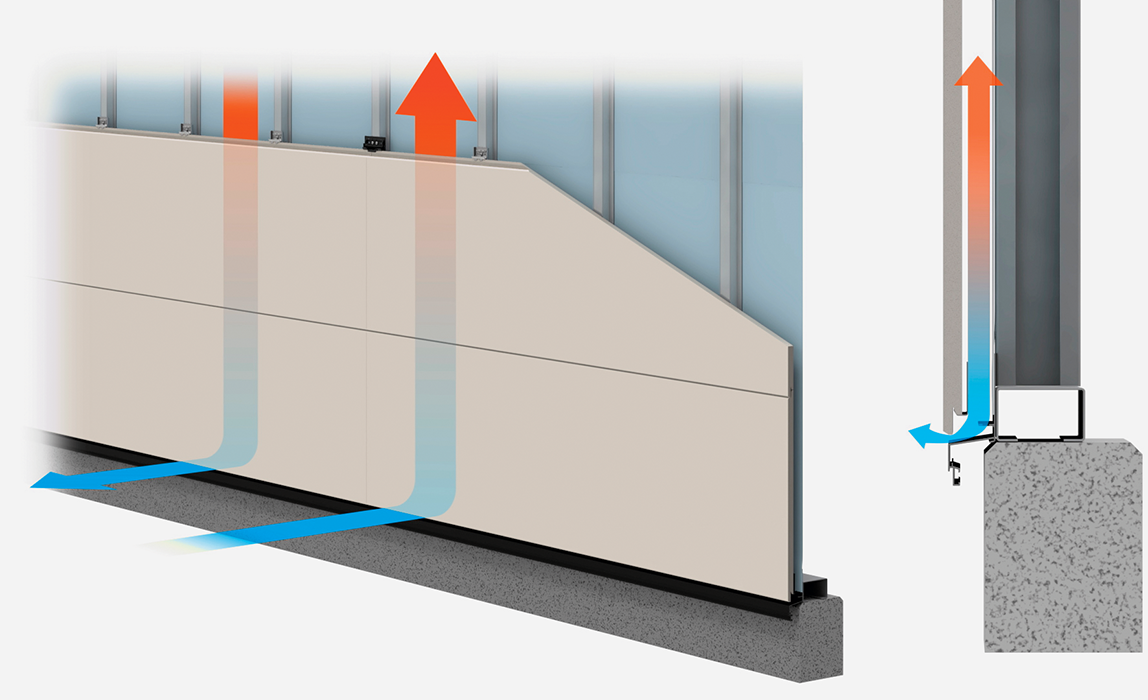

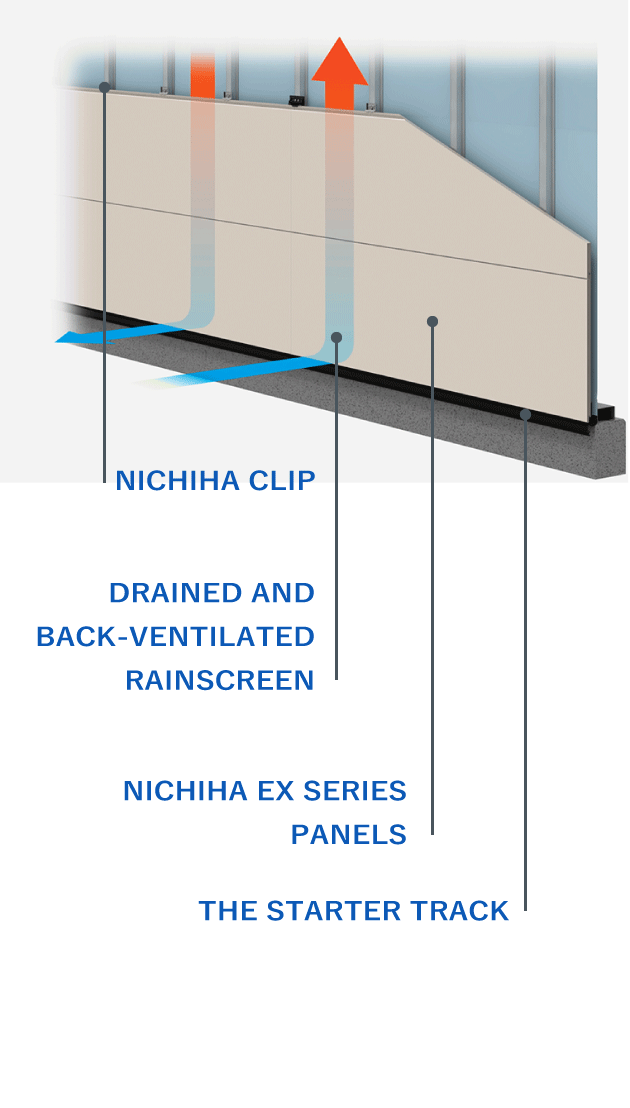

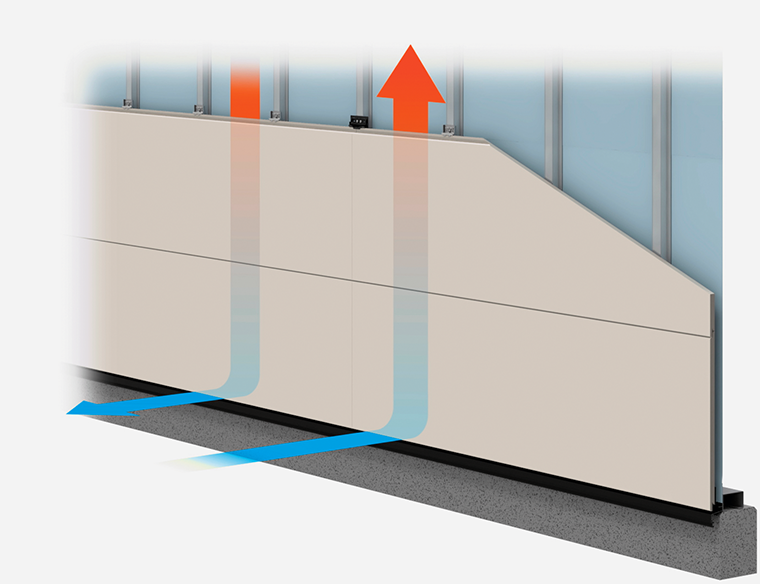

Go beyond our durable panels and discover a meticulously engineered moisture management system that provides a vertical drainage point for air and moisure to exit.

Products can be installed year round in any climate across the country. No geographical restrictions means more possibilities.

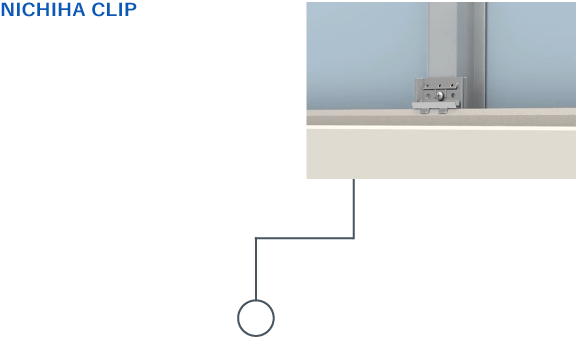

creates a hidden fastening system

that all but eliminates face

fastening. Installation is quick and

easy and never requires speciality

subcontractors.

are lightweight, easy to handle and available in a virtually endless color palette and a diverse offering of textural finishes.

pulls double-duty. It ensures a fast, level installation, and its patented drainage channel directs water out and away from the base of the wall.

design allows water to escape and air to circulate, reducing the risk of mold and water damage inside the building.

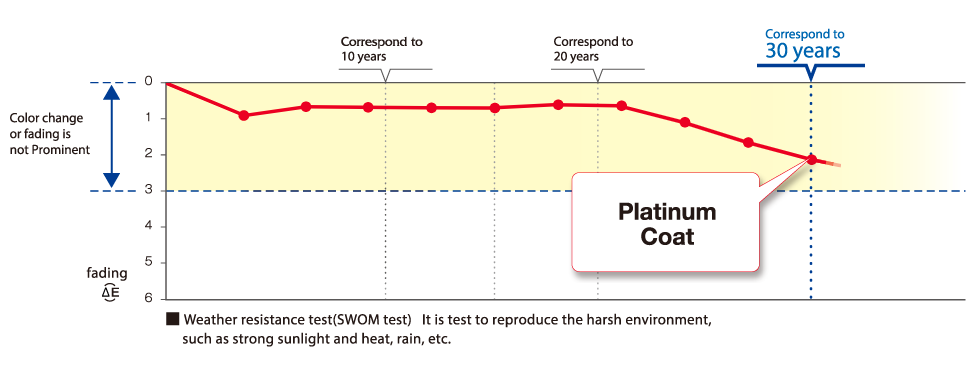

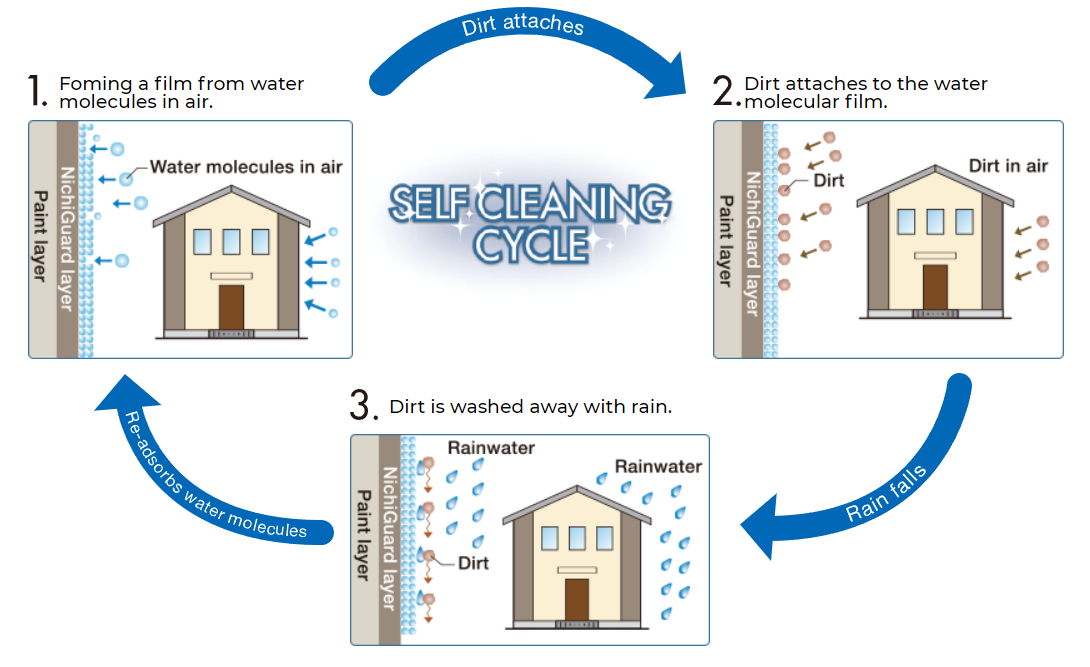

The panels have a special NichiGuard™ self cleaning coating applied during the manufacturing process. Panels include PlatinumCoat™ technology to protect against UV damage and color fade.

|

|

|

|

Fire safety and compliance become a significant issue for the construction industry on the back of several tower fires which have attributed highly combustible aluminum cladding as a significant contributor to the spread of fire. More than ever, all stakeholders within the building process must be more accountable and informed when specifying non- combustible cladding products and systems.

Nichiha EX Series is deemed to be non-combustible as it is classified as A2, s1-d0 in the European Reaction to Fire classification system.*

In addition, systems using Nichiha EX Series panels for their facade were tested in various countries as shown Table 1. It is notable that the system including Nichiha EX Series became the first fiber cement facade product which passed one of the most severe facade testings in the world, the Australian fire propagation testing and classification (AS 5113).

<Table 1>

*Note : Not all the panels are classified as A2, s1-d0 |

|

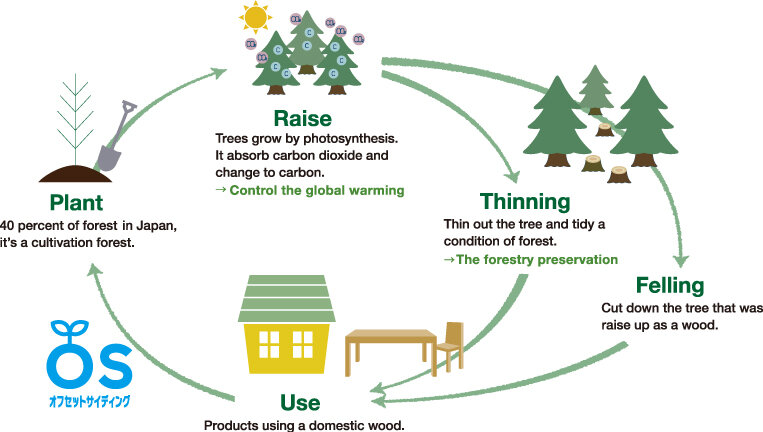

You can’t keep forests unless you cut down trees. It sounds like a contradiction, but it is true. “Wood thinning” is for keeping distance among trees and provide trees enough light evenly. “Regeneration cutting” is for cutting down trees. Grow trees, cut down the trees, and plant new trees. Young trees can absorb a lot of CO2 by doing that repeatedly, which leads to prevent from Global warming.

However, aging of forests is getting a serious problem due to the lack of necessary care by low demand of domestic timbers. The passion about trees and desire of protecting woods and promoting the use of domestic timbers produced “NICHIHA Offset Siding” by utilizing wood chips.

This is an exterior wall product made by utilizing wood chips of domestic wooden chips. It corresponds to Excelard and W series. At the 17th Conference of Parties to the United Nations Framework Convention on Climate Change(COP17) in 2011, it is agreed to count the emission rate of carbon from cut domestically-produced woods when the wood product was discarded. Therefore, the exterior wall material using the domestic woods is admitted as a storage of carbon until its disposed.

|

© NICHIHA Co.,Ltd All Rights Reserved.